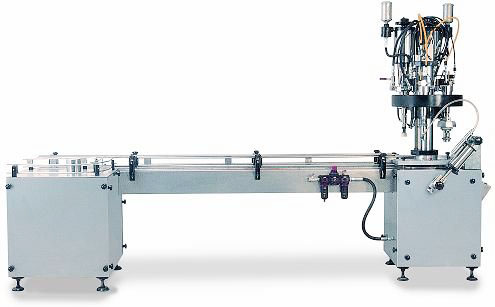

HM 800 OD - Full Automatic Aerosol Filling Machine

Product Details

The machine consists of two units :

- Rotating empty container feeder

- Rotating Aerosol filling, crimping and gassing unit

The Working Principle

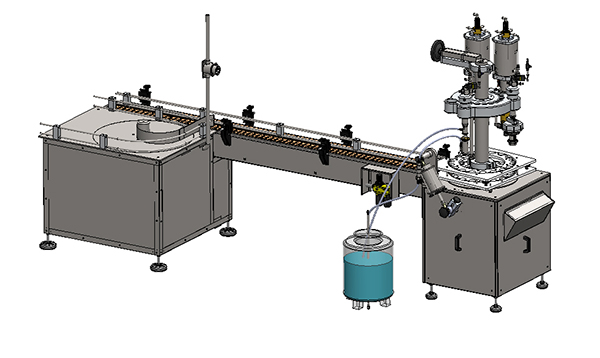

1st unit - Rotating Empty Container Feeder :

The unit automatically feeds the aerosol cans onto conveyor, the speed can be adjustable.

2nd unit - Rotating Deodorant Filling - Crimping - Gassing Unit

The unit automatically fills the aerosol product into the cans, crimps their valves and pumps gas into cans.

Empty containers enter rotating star system one by one to be filled automatically.

After the filling process the operator puts the valves manually by hand on the already filled containers, then the valves are crimped on to the containers.

After the crimping process, the gassing starts. On the 1st gassing station, the container fills half of the container, and the remaining on the 2nd unit. The reason of two station is to make to system faster

After the gassing process , the aerosol cans move on conveyor until end of line to be picked up for boxing.

The machine does work only if :

- Enough air pressure provided

- Conveyor is moving

- Liquid filling wouldn’t start if the container is not empty

- Crimping wouldn’t start if the container is not in place

- Gassing wouldn’t start if the container is not crimped

- Gassing wouldn’t start if he requested gas isn’t provided

Filling of liquid and gas pumping are volumetric and with high accuracy. The machine is pneumatic , and only the conveyor motor is electrical. Conveyor motor and start-stop switches are EXPROOF. The maintenance, and usage of the system is very easy, simple and safe against flaming and explosion.

- Pneumatic parts are made by WERKOM ( Italian made )

- Conveyor Exprof Motor is made by ISGEV ( Italian made )

- All other remaining parts are made in Turkey.

Technical Specifications

| Liquid Filling Volume Range : | 25 ml – 250ml , 1 piece |

|---|---|

| Crimping Unit : | 1 unit |

| Gas Filling Volume Range : | 10 ml – 200 ml , 2 pieces |

| Sensitivity of Filling : | + / - % 0.3 gram |

| Control System : | Pneumatic, Weirkom brand-German made |

| Gas types to be Filled : | LPG , FREON DIMETILEN ETER |

| Capacity : | 1.000 – 2.000 pieces / hour |

| Air Pressure : | 8 bar |

| Air Consumption : | 1.400 liters / minute |